THR500 Magnetic Stirred high pressure vessel 500ml

Basic Info

Model No.: THR500

Product Description

1.Toption THR series lab magnetic stirred high pressure reactor is a stirring and reacting device, which is used for kinds of chemical materials which are Gas-liquid, liquid-liquid, liquid -solid or gas-liquid-solid three-phase to reactand stir fully under the high pressure, vacuum, high temperature, up to strength mass and heat transfer process.

2.The maximum operating temperature of THR High Pressure Reactor is 250℃, use corrosive medium to do reaction, PTFE inner is optional, but its high temperature resistance is 180℃,so if the corrosive medium temperature is over 180℃, please choose other material reactors.

3.THR Series High Pressure Reactor adopt module heating method, which is quick heating and precise temperature control. THR series all are internal magnetic stirring, when magnetism arrive 300°, degaussing phenomenon will happen, so if operating in over 300° condition, please choose TOPTION MHR Series High Pressure Reactor.

Rrmark:

1. Max volume 2000ml could be customized.

2.Suitable for the material which temp <250℃ and is nonmagnetic.

3.Temperature timing set, temp. set when working, this function is optional.

Chemistry, Pharmaceutical, Macromolecule, Metallurgy, Environmental Protection,etc, chemical process areas. For instance: high pressure reaction, hydrogenation reaction, catalytic reaction, synthetic process, pharmaceutical synthesis, high pressure polymerization, nano synthesis, conditions screening, crystallization screening, combinatorial chemistry, biomass conversion, supercritical reaction, hydrothermal reaction, polymer synthesis, electrochemical corrosion testing, infrared detection,etc.

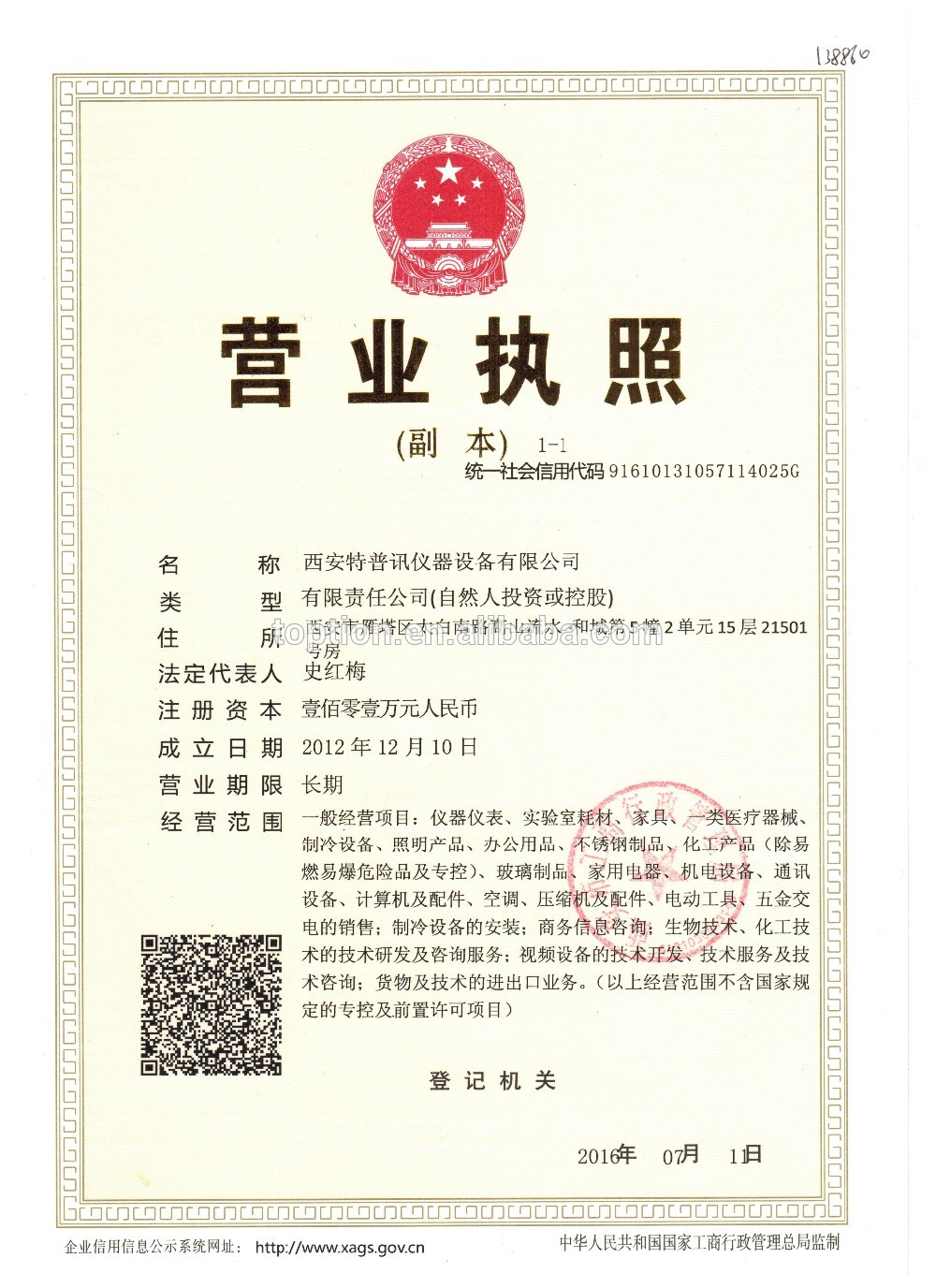

TOPTION as a professional lab solution provider is specialized in manufacturing and selling photochemical glass reactor ,UV glass reactor system, xenon glass reactor, single-layer glass reactor,double-layer glass reactor, three-layer glass reactor,thermostatic equipment, ice maker, Ultrasonic Instrument, spray dryer, air dryer,extracting device and so on, who are work in chemistry, biology, pharmaceutical, environment analysis, food, academic research, etc. Regardless of the field you work in, we keep striving for the same goal: to provide you with the most suitable solutions & products, to make your research more accurate & efficient.

TOPTION has passed the “ISO9001:2008 Quality Management System”certification and some of products have passed CE certification,the quality can be assured.

Packing:

-Standard wooden case.

-Both neutral and customized packaging can be available.

Shipping:

-We can ship the goods to you by International Express such as DHL,UPS,TNT,EMS and so on, you can also choose the appropriate one based on your timeline and budget. Besides,you can choose to use your own forward.

Pre-Sales Service:

1. Inquiry and consulting support.

2. Quick response with detailed quotation

3.Confirm price, quantity, shipment, lead time and payment terms)

4.Make order and sealed PI. (Trade assuranceorder is recommend to new clients for securing payment)

After-Sales Service:

1. One year warranty for the products described here.

2. Beyond the warranty period, product problems can also be solved by our company, but charge component cost and maintenance cost properly.

3.Reliable quality and thoughtful after-sale service: If you encounter problems when using our products, please contact us by telephone or e-mail, we will be ready to provide consulting, maintenance and other services immediately.

Q: What is your MOQ?

A:1 set.

Q: How long is your delivery time?

A: Generally it is within 3 working days after receiving the payment if the goods are in stock. Or it is 5-10 working days if the goods are not in stock, depending on order quantity.

Q: How to choose suitable equipment ?

A:Tell us your work specific requirements ,then we will recommend you suitable equipment to you.

Q: How to solve the equipment trouble during using ?

A: Please email us about problem with pictures or a small video will be better,we will find the problem and solve it. If broken, we will send you a new free part if in the warranty period.

Product Categories : Chemical Synthesis Reactor Series > High Pressure Reactor

Premium Related Products