High quality lab process glass reactor 1000ml glass reactor

Basic Info

Model No.: TOPT-1L

Product Description

High quality lab process glass reactor 1000ml glass reactor

Toption Jacketed Glass Reactor are available with different options, depending upon their size & their utility. We will glad to assist you in finding a suitable solution for your process requirement.

Below options are available for Jacketed Glass Reactor Unit:

1. Stirrer Drive: Non-Flameproof or Flameproof Motor, 192 RPM with speed regulator.

2. Stirrer material of construction: Glass or PTFE Lined.

3. Stirrer shape: Glass Impeller Stirrer with PTFE Blades, Vortex Stirrer, propeller stirrer & anchor stirrer.

4. Stirring Assembly: Stirring Assembly with bellow seal or with mechanical seal.

5. Supporting Structure: Carbon Steel, Epoxy coated Carbon Steel, Stainless Steel 304 & Stainless Steel 316. All structure are available in Trolley mounted form.

6. Closing Valve: Drain Valve or Flush Bottom Outlet Valve.

This TOPT-10L Double Layer Glass Reactor /laboratory reactor/jacketed glass reactor adopts GG17 high boron silicon as material ,digital display.And it's high quality has passed CE certification.

Remark:

1. Custom sevice is welcome here.

2.we also have the match equipment for the glass reactor.

3.If the voltage and plug need to be replaced, pls give clear indication when in contact us.

Key Features of the high quality lab process glass reactor 1000ml glass reactor:

1. Double glass reactor using VVVF, AC Induction Motor. Speed constant, no brush, no sparks, security staTOPTe, continuous working.

2. Complete glass reactor adopts GG17 high borosilicate glass production good chemical, physical properties.

3. Glass interlayer Interface communication on hot oil through cycle do Heating Reaction, Tung on cryoprotectants can be hypothermia reaction.

4. Can normal temperature reaction, pass last tap namely quickly will reflect heat away.

5. Decentralization material mouth with flange mouth and PTFE valve, container no dead corner detachaTOPTe easy solid materials outfeed.

6. 5 reactor lid, large mouth design easy clean standard mouth socket selectaTOP Te assem TOPT reflux, distillation synthesis device.

Side discharge valve (standard or preload)

No dead angle, air isolated discharge. Max drift diameter 20mm. Preload discharge valve is able to decrease flask crack risk due to improper over-screw of discharge valve. Customization of TOPTION big capacity glass reactors.

Flask cap (≥10L)

Flange quick press ring

One-piece quick clip design. Offer new experience on easy, reliable, and high sealing connection .

PTFE flush discharge valve

No-sample accumulation in valve during operation and discharge. Max drift diameters is 20mm.

Glass reactor lid

Reactor stirring paddle

TOPTION as a professional lab solution provider is specialized in manufacturing and selling single-layer glass reactor,double-layer glass reactor, three-layer glass reactor, freeze dryer, Hydrothermal Synthesis Reactor, photochemical glass reactor , thermostatic equipment, UV glass reactor system, xenon glass reactor, ice maker, Ultrasonic Instrument, spray dryer, air dryer,extracting device and so on, who are work in chemistry, biology, pharmaceutical, environment analysis, food, academic research, etc. Regardless of the field you work in, we keep striving for the same goal: to provide you with the most suitable solutions & products, to make your research more accurate & efficient.

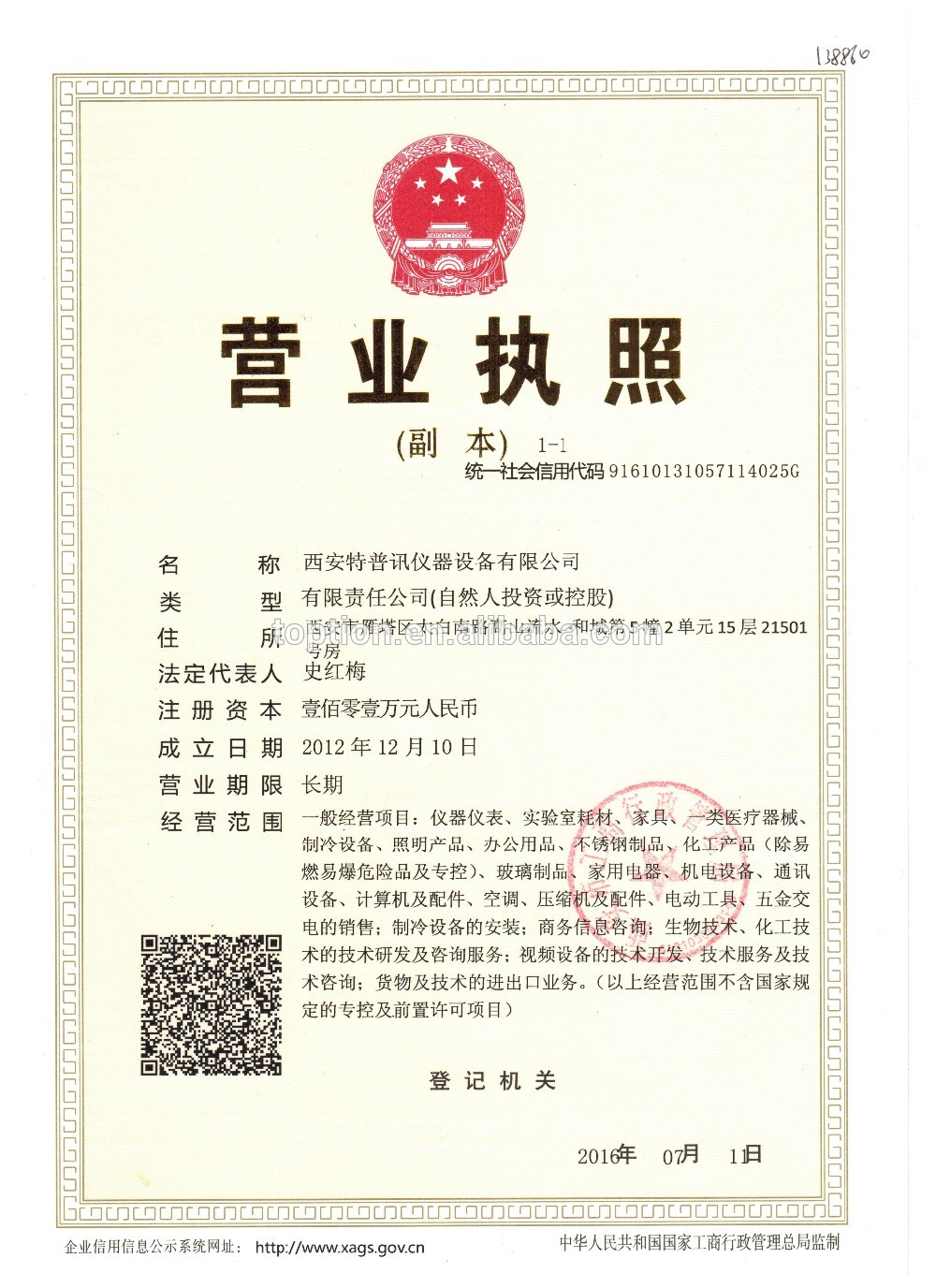

TOPTION has passed the “ISO9001:2008 Quality Management System”certification and all of our glass reactor have passed CE certification,the quality can be assured.

Packing of the high quality lab process glass reactor 1000ml glass reactor :

-Standard wooden case.

-Both neutral and customized packaging can be available.

Shipping:

-We can ship the goods to you by International Express such as DHL,UPS,TNT,EMS and so on, you can also choose the appropriate one based on your timeline and budget. Besides,you can choose to use your own forward.

Pre-Sales Service:

1. Inquiry and consulting support.

2. Quick response with detailed quotation

3.Confirm price, quantity, shipment, lead time and payment terms)

4.Make order and sealed PI. (Trade assuranceorder is recommend to new clients for securing payment)

high quality lab process glass reactor 1000ml glass reactor

After-Sales Service:

1. One year warranty for the products described here.

2. Beyond the warranty period, product problems can also be solved by our company, but charge component cost and maintenance cost properly.

3.Reliable quality and thoughtful after-sale service: If you encounter problems when using our products, please contact us by telephone or e-mail, we will be ready to provide consulting, maintenance and other services immediately.

Q: What is your MOQ of the high quality lab process glass reactor 1000ml glass reactor?

A:1 set.

A: Generally it is within 3 working days after receiving the payment if the goods are in stock. Or it is 5-10 working days if the goods are not in stock, depending on order quantity.

Q: How to choose suitable glass reactor ?

A:tell us your work flow and requirements ,then we will recommend you suitable equipment according to yourrequirements, application experience and feedback from our clients.

Q: How to solve the glass reactor trouble during using ?

A: Please email us about problem with pictures or a small video will be better,we will find the problem and solve it. If broken, we will send you a new free part if in the warranty period.

Product Categories : Chemical Synthesis Reactor Series > Double Layer Glass Reactor

Premium Related Products